Gurelan and quality: the engagement driving this project

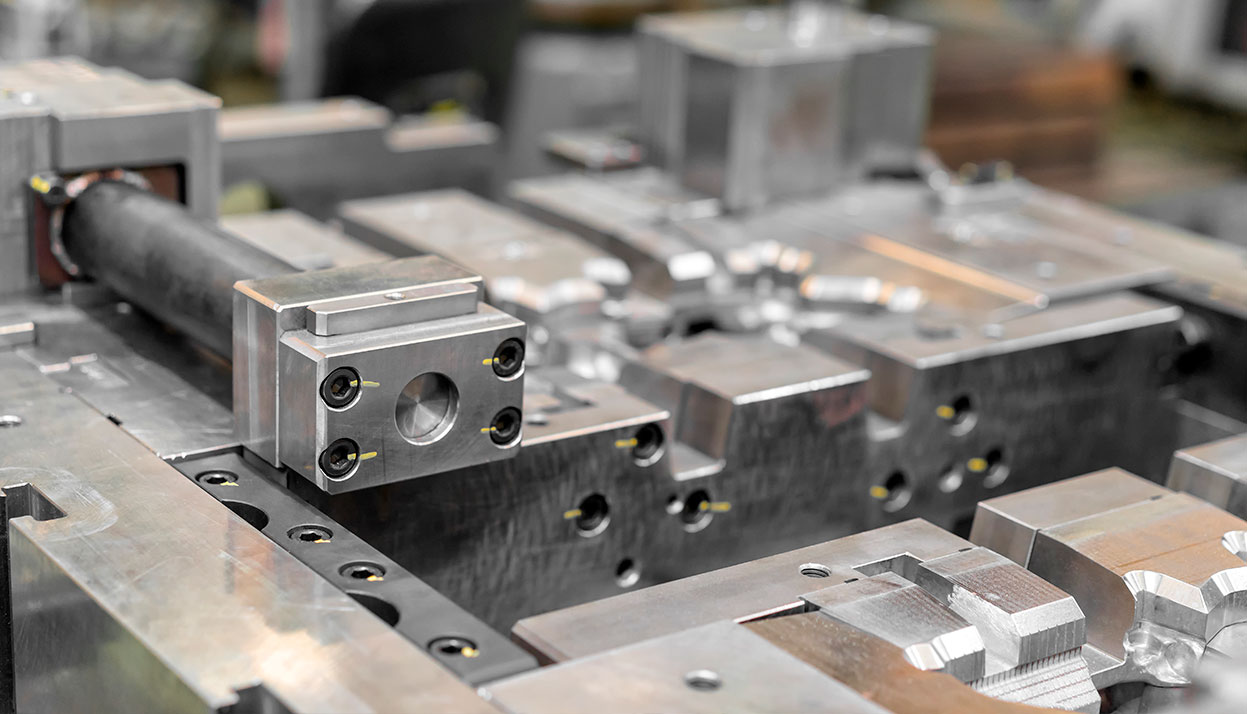

Quality is the most important value for a company as Gurelan. Wherever the client may be, no matter the industry: the best business card is the confidence that comes from this quality built up over decades. As such, Gurelan renews its ISO 9001 and ISO 14001 standards for quality management and environmental protection to further promote this company´s brand, founded in 1934, as a benchmark in the die-casting of Zamak, Magnesium and Lead parts for all kinds of industries.

Read more