- 15-09-2020

- Articles

Gas-assisted injection moulding: the future for electric vehicles

The automotive sector is already preparing for the next step: optimisation of the industrial processes that will enable the definitive take-off of the electric vehicle. Today, gas-assisted injection moulding can further reduce the weight of future electric vehicles without jeopardising safety and comfort. As part of its strategy of continuous innovation, Gurelan is studying how lighter parts of Zamak and Magnesium could be obtained thanks to a new gas-assisted technique that produces hollow sections out of thick metal parts.

As we already know, hot chamber injection moulding is an efficient and cheap process, offering a wide range of components for the automotive sector and all kinds of applications such as electronics, electrical equipment, machine tools... Depending on the injected material (Zamak, Magnesium or Lead) and the characteristics of the mould, Gurelan can cast different parts with varying levels of resistance, lightness and useful life.

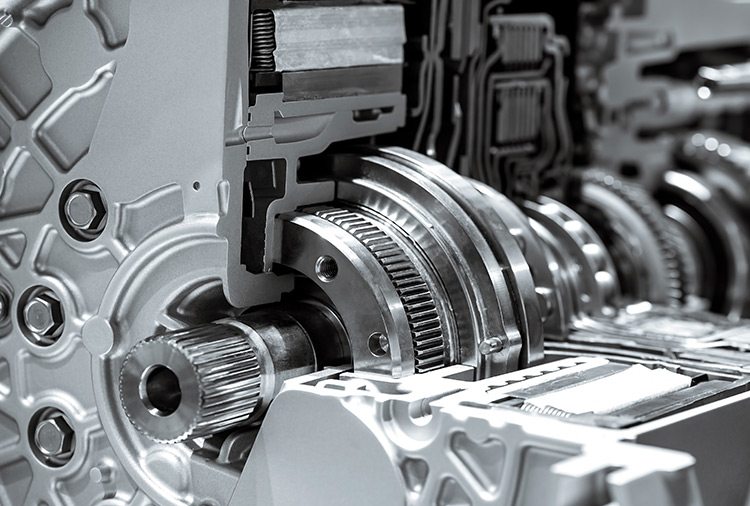

Today, lightweight design concepts are at the heart of the upcoming electric vehicle revolution. Forcing molten metals into a mould at high speed and pressure – such as high-pressure die casting processes used by Gurelan for automotive – provides manufacturers flexibility to create complex components. In addition to their reduced weight, these products are also strong and resistant. The considerable increase in the use of light metal castings in vehicles, such as Zamak or Magnesium, presents an opportunity for growth to all kinds of sectors, but especially to the automotive sector.

What is gas-assisted injection moulding?

Now, a solution developed thanks to European funds MAGIT provides answers to the demands of the sector in terms of weight reduction, strength and cost. Researchers implemented a versatile alternative to more traditional injection moulding techniques called gas-assisted injection moulding.

As part of its continuous innovation strategy, Gurelan is studying this and other injection techniques to determine their feasibility and effectiveness in the future. Now, it´s time to explain this process. In short, new gas-assisted injection technology allows the manufacture of high-pressure die-casting parts with a hollow section inside without putting any cores inside. How is this possible? It´s actually quite simple...

Using high-pressure air to displace and push material in mould cavities, gas-assisted injection is an innovative method that was originally used in plastic processing to produce parts with hollow sections. Unlike Gurelan´s pressure injection moulding, this technology makes it possible to inject gas into an Aluminium or a Magnesium part by pushing out the still molten mix into a spill-over cavity.

Which are the advantages of gas-assisted injection moulding?

Constantly increasing demand for pressure moulding of light materials such as Zamak or Magnesium, faster cycles and lower production costs make gas-assisted injection technology a unique process with huge potential, repeatable and reproducible in several industrial applications.

Importantly, the manufacturing of complex hollow parts does not require additional upstream and downstream processes, an option which is not possible when using other casting techniques.

Furthermore, the gas-assisted moulding technology does not cause any sink marks and voids or any dimensional distortion, thereby allowing new levels of freedom in the design of thick-walled, hollow components.

Gas-assisted moulding: an innovative and adaptable technique

In particular, the core element of the system, the compressor, contains all relevant systems for control, gas and hydraulic pressure. The accumulator next to the mould shortens the routes to the die module, while the latter takes charge of the gas supply, hydraulics and the cooling water line. All these modules can be mounted on a conventional die casting machine without any modification except from providing an interface of some machine signals.

Gurelan has been innovating for over 80 years to offer the most efficient, economical and highest quality solutions for all types of hot chamber pressure die castings. Automotive, electronics, jewellery, furniture, electrical equipment... Zamak, Magnesium or Lead injected components are able to gather all the required qualities for each type of sector, for all their applications. Now, we are studying gas assisteded injection as a possible future solution to extend services, quality and range of applications.