- 26-08-2020

- Articles

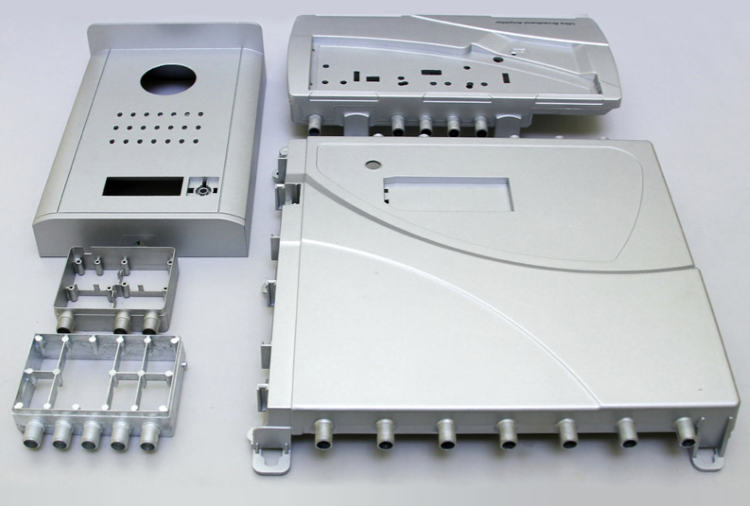

Zamak parts for electronics: a smart solution to meet the sector´s needs

The COVID-19 pandemic has dramatically accelerated the development of new technologies. In this new context defined by the growing need for new electronic devices of all kinds, die casting of Zamak parts for the electronic industry has reinforced its strategic value as an effective, economical and top quality solution when producing certain components destined for the electronics sector.

Medical devices, systems for capacity control and safety distance monitoring, new equipment specifically designed to reduce the expansion of the COVID-19... The boom in new technologies generated by the pandemic has practically become a new industrial revolution in its own terms. Within the broad spectrum of the electronics sector, the design and manufacture of components stands out for its specific weight in the industry as well as for being one of the most technologically dynamic branches.

Under these circumstances, the demand for efficient and quality solutions in the electronics sector opens the way for the introduction of Zamak die castings for the electronic industry. Why choosing this smart solution adapted to the objectives of large manufacturers?

Why using Zamak in electronics?

One of the great advantages of manufacturing Zamak injected parts for electronics are the detail level and the quality of the finished product. Today, customers in the electronics sector rely on automatic assembly lines, and therefore the flatness requirements are much more demanding in these cases. In this sense, the quality of Gurelan´s die cast solutions leads this domain.

For example, the injection moulding process allows the manufacture of parts with male screws integrated within the design itself, avoiding any subsequent machining or welding operations.

In this regard, products and components manufactured and assembled by electronics companies are at the core of these increasingly complex and changing technologies, that will affect all aspects of modern life. Now, developers of new technologies are requiring the advantages that only die-casting of Zamak parts can offer for the electronics sector.

Zamak parts: a solution to the new global challenges

Designers and producers of new technologies are facing many challenges in this dynamic and fast-moving market: global competition is now setting the market trend, making the need for superior quality products more essential than ever.

Consequently, post-Covid technology will be marked by the constant need to lower costs, while limiting dependence on sources of supply distributed throughout the world. This is the ideal ecosystem for the spread of Zamak parts for the electronics sector.

Zamak for electronics: die-casting solutions for decades

Gurelan has been producing Zamak parts for electronics for decades. Why? Zamak is a very economical, strong and durable material. Thanks to its optimal plastic deformity, die-casting parts for the electronics sector allows to develop almost finished components, with the highest level of detail and without errors: Gurelan manufactures its own moulds, controlling the quality of the process from start to finish.

From the design of the Zamak die-cast part to its finishing, Gurelan guarantees the highest quality standards and meets the strictest requirements when producing elements for the electronics sector, supported by the reliance of large industrial groups and decades of experience in hot-chamber die-casting of Zamak, Magnesium and Lead parts.

Thanks to technical expertise and a high degree of automation, Gurelan is a small but very competitive company in Europe. Dealing with such different problems has allowed Gurelan to acquire the required know-how to meet 100% of the most demanding customers´ requests.